Basics of Cost Accounting: Product Costing - HostExpert

November 26, 2021

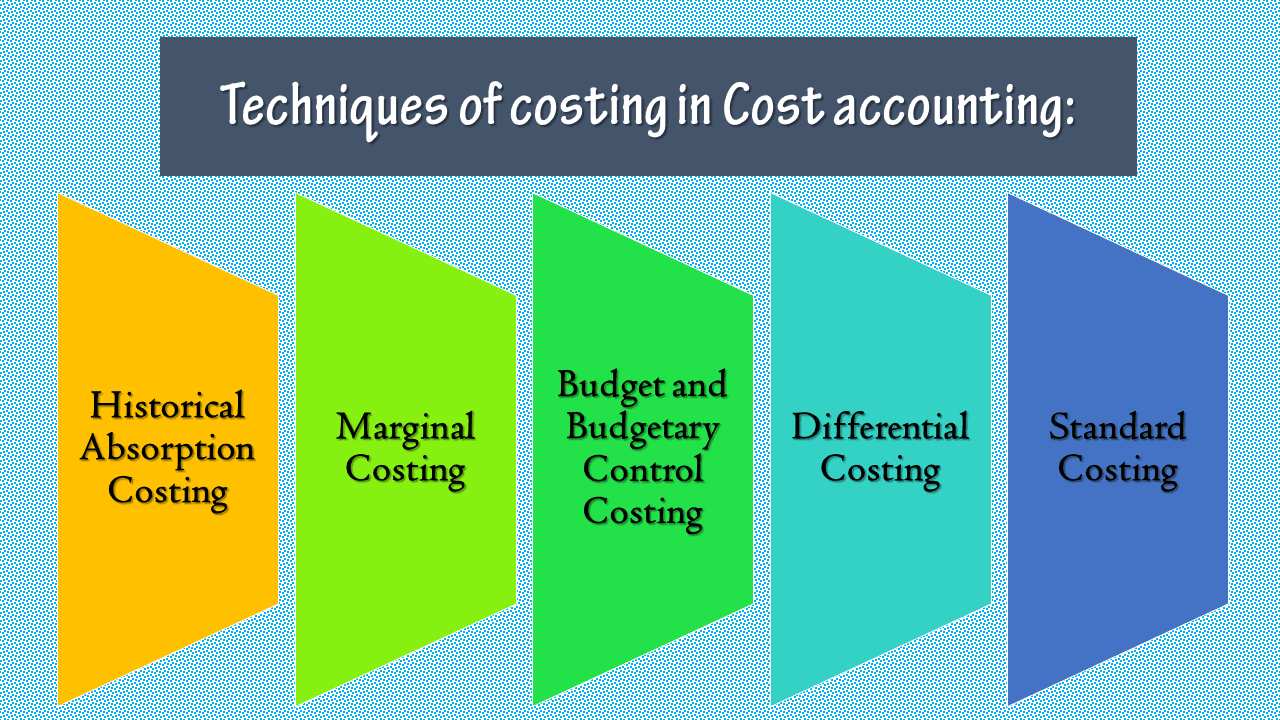

These costs are then used as a reference to compare with the actual costs during and after production. This method allows you to spot any differences and make adjustments if needed. If actual costs are higher than expected, it might mean something isn’t running efficiently.

What are the different types of cost drivers under ABC?

The costs in goods sold total food sales are the amount of money a customer has spent to purchase ingredients and inventory over a period. If a particular product makes profit, it can make sense based upon its profitability. But you need information to make sure that everything you do in your business succeeds. List all the items that have arrived in your mailbox for the first time in a month. The best costing method depends on various factors, including your business size, production process, and industry requirements.

A Look Back at the History of Activity-Based Costing

In activity-based costing, overhead costs are assigned to activities rather than products. A cost pool is a group of related costs incurred when performing a particular activity. The process costing method first considers the total number of units passing through a particular part of the production process, then tallies up the total costs and divides the result into a per-unit cost.

Pricing Psychology:

Have you ever opened your banking app and been struck with a wave of panic? Or found yourself staring at your phone screen in utter bewilderment, wondering where all your money went? These are all-too-common experiences that can be easily remedied with a well-implemented product costing system. Thus, it is believed that activity-based costing helps in presenting a more realistic picture of the behavior of costs. As a result, traditional systems tend to over-cost high volume products, services and customers and under-cost low volume.

Explanation of Activity-Based Costing

For the chair example, this would include the wood, nails, glue, and labor, among other costs. If these costs exceed the selling price of the chair, then your business is undoubtedly making a loss and needs to understanding the balance sheet re-evaluate the product costing system immediately. Using ABC, overhead costs are traced to products and services by identifying the resources, activities and their costs and quantities to produce output.

- To make sure that all company costs are covered and that the development and accounting teams set a price that ensures a profit, costing is crucial.

- Once you’ve chosen your inventory costing method, you’ll be expected to stick to this method each financial period – so take the time to understand which approach is right for you.

- Overheads are indirect costs since these can’t be directly linked to the production of goods.

- By investing in robust product costing practices, businesses position themselves for success and create a strong foundation for long-term prosperity.

Obtain Ingredient Prices:

You may be focused on reducing costs or improving pricing strategies or even streamlining your production processes. The real challenge comes when you need to figure out which costing method is the right one for your business. Below, we address a series of questions to help you determine the ideal costing method for your manufacturing business. Target costing starts with a target cost based on market prices and then finds ways to meet it. It’s ideal if you’re operating in a competitive market where price is king, but it’s not the most straightforward method on this list. Target costing requires cross-functional collaboration across different departments to arrive at a cost that meets both customer expectations and profitability goals.

Product cost plays a crucial role in determining the pricing strategy and overall profitability of a product or service. Typical attributes include the number of direct labor hours required to manufacture a unit, purchase cost of merchandise resold or the number of days occupied. Activity based Costing (ABC) is a systematic, cause & effect method of assigning the cost of activities to products, services, customers or any cost object. This lack of accuracy has led cost accountants to search for new, fairer ways to charge production units for their share of indirect expenses. Meanwhile, businesses are now paying more attention to whole quality products.

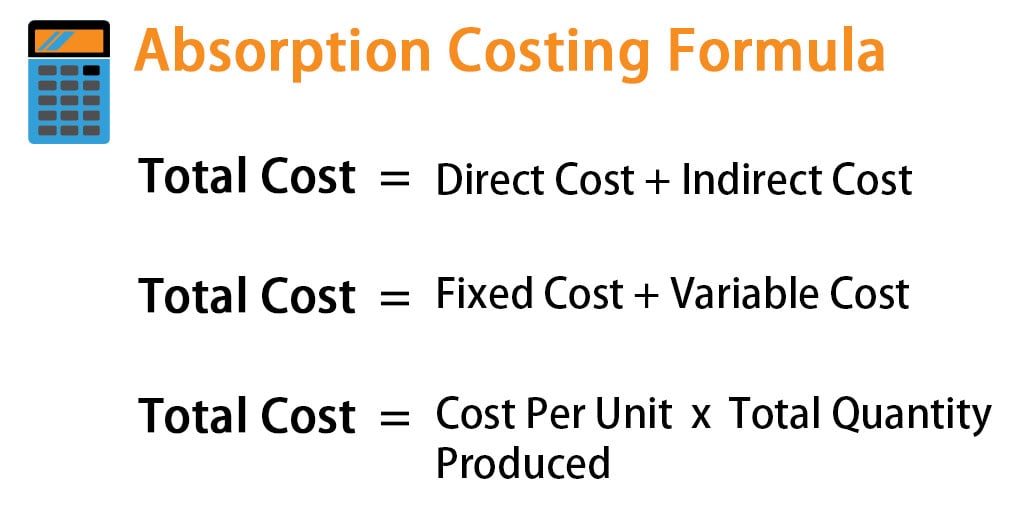

As you can see there is a heavy focus on financial modeling, finance, Excel, business valuation, budgeting/forecasting, PowerPoint presentations, accounting and business strategy. Absorption costing results in a higher net income compared with variable costing. Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more. On the balance sheet, accountants list the ending inventory balance as a current asset. On the income statement, accountants also include the change in inventory as a component of COGS.

You also need to invest in marketing, sales, customer support, legal, and more to ensure your product reaches the hands of the customers you want to serve. Are you going to hire employees, an agency, or freelancers to build your product? However, it may pay off in the long run if they deliver high-quality code. Some cost-saving measures, like hiring junior developers, may result in several issues later on in the development process. That is why an essential aspect of any ABC endeavor is to get a clear picture of the activities a business area performs. Some ABC systems rank activities by the degree to which they add value to the organization or its outputs.

Calculating the cost driver rate is done by dividing the $50,000 a year electric bill by the 2,500 hours, yielding a cost driver rate of $20. This costing system is used in target costing, product costing, product line profitability analysis, customer profitability analysis, and service pricing. Activity-based costing is used to get a better grasp on costs, allowing companies to form a more appropriate pricing strategy. Product costing can be made much easier with the help of manufacturing software. A proper ERP/MRP system can help you easily track the costs incurred with manufacturing products. The best solutions initially estimate and later, after production, accurately calculate the cost per unit based on some of those inputs.

The ending inventory will include $14,000 worth of widgets ($7 total cost per unit × 2,000 widgets still in ending inventory). Manufacturers will prioritize direct costs, or expenses directly related to manufacturing. In contrast, businesses must take indirect expenses and/or overhead costs into account when making long-term pricing and profitability decisions. Accurate inventory costing is essential for determining the true cost of your products. Katana enables you to assign costs to your raw materials, components, and finished goods, ensuring that your inventory valuation reflects the actual expenses incurred.

-

17+ Greatest Crypto Local casino Which have 100 percent free Spins and Bonuses 2025: Better Selections! March 4, 2025 No Comments

-

-

Online casino games On line as opposed to 150 options arabian caravan costs: Play with Zero-Present March 4, 2025 No Comments